CMX-F44: Green, lightweight nylon fabric coated with heat cured silicone release solution to aid removal of laminate cured to 204 ° C (400 ° F).

CMX-F3: Non-porous, PTFE coated, plain woven fiberglass fabric designed as a release fabric to prevent resin from flowing in from the release fabric. Operates up to 550 ° F (288 ° C).

CMX-F10: Non-porous, PTFE-coated, plain woven fiberglass fabric is designed as a release fabric to prevent resin from flowing into the fabric. Operates up to 550 ° F (288 ° C).

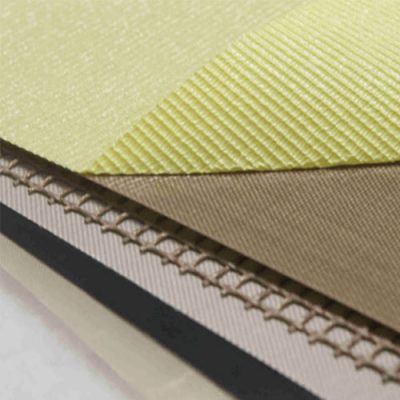

CMX-F3PM: Brown, lightweight, porous, PTFE-coated glass fabric, ideal for use in flat or single curved molds in most extreme temperature and pressure conditions. 608 ° F (320 ° C).

CMX-F5PM: Brown, medium weight, porous, PTFE coated glass fabric, ideal for use in flat or single curved molds in extreme temperature and pressure conditions. 608 ° F (320 ° C).

CMX-F10PM: or single bevel molds in extreme temperature and pressure conditions up to 608 ° F (320 ° C). Brown, heavy, porous, PTFE coated glass fabric, ideal for use on level floors

CMX-F5: Non-porous, PTFE-coated, plain woven fiberglass fabric is designed as a release fabric to prevent resin from flowing into the fabric. Operates up to 550 ° F (288 ° C).

CMX-F25W: Heavy weight PTFE coated glass fabric mesh, normally used as a reusable edge breather around the periphery of tooling. (260ºC / 500°F)

CMX-F30W: Heavy weight PTFE coated glass fabric mesh, normally used as a reusable edge breather around the periphery of tooling. (260ºC / 500°F)